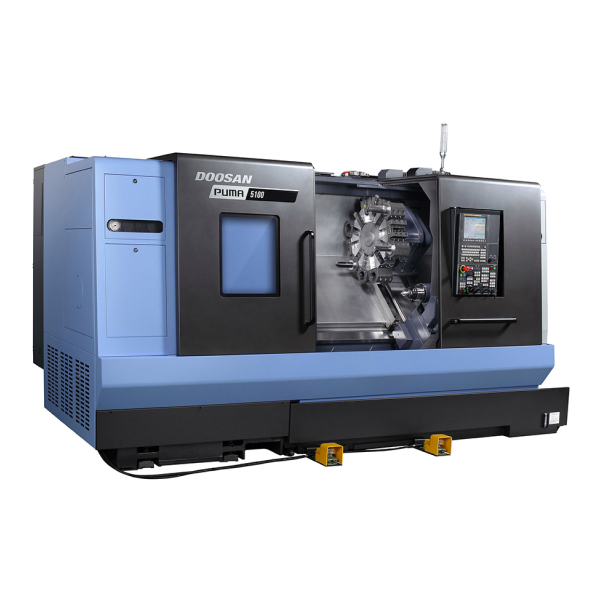

PUMA 5100 – это мощные, усиленные и надежные токарные центры, оснащенные передовыми высокоскоростными шпинделями, револьверами с сервоприводом и коробчатой направляющей для обеспечения повышенной жесткости, а также улучшенной производительностью обработки.

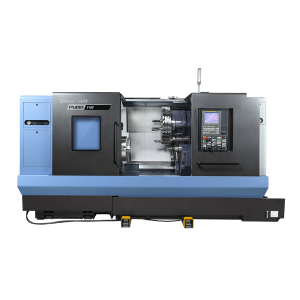

Токарные центры

- Макс. диаметр обработки 360 мм

- Макс. длина заготовки 170 мм

- Макс. Мощность мотора 0 кВт

- Макс. диаметр обработки 900 мм

- Макс. длина заготовки 5050 мм

- Макс. Мощность мотора 55 кВт

- Макс. диаметр обработки 450 мм

- Макс. длина заготовки 765 мм

- Макс. Мощность мотора 15 кВт

- Макс. диаметр обработки 830 мм

- Макс. длина заготовки 780 мм

- Макс. Мощность мотора 37 кВт

- Макс. диаметр обработки 370 мм

- Макс. длина заготовки 1250 мм

- Макс. Мощность мотора 0 кВт

- Макс. диаметр обработки 380 мм

- Макс. длина заготовки 610 мм

- Макс. Мощность мотора 18.5 кВт

- Макс. диаметр обработки 481 мм

- Макс. длина заготовки 1603 мм

- Макс. Мощность мотора 35 кВт

- Макс. диаметр обработки 790 мм

- Частота вращ. шпинделя 2000 об\мин

- Макс. крутящий момент 1279 Нм

- Макс. диаметр обработки 1100 мм

- Макс. длина заготовки 1000 мм

- Макс. Мощность мотора 60 кВт

- Макс. диаметр обработки 650 мм

- Макс. длина заготовки 3152 мм

- Макс. Мощность мотора 45 кВт

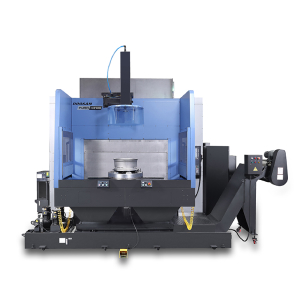

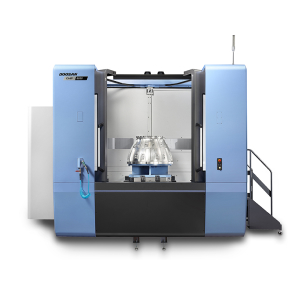

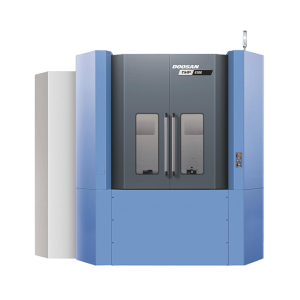

Обрабатывающие центры

Новые вертикальные обрабатывающие центры DNM надежные, точные и обладают эксплуатационной гибкостью и улучшенной производительностью.

Все станки оснащены мощными шпинделями с прямым приводом, обладают большой областью обработки и снабжаются системами управления ЧПУ на выбор – Fanuc, Heidenhain или Siemens.

- Макс. длина обработки 4070 мм

- Макс. мощность мотора 37 кВт

- Крутящий момент 4200 Нм

- Размер стола 350×350 мм

- Макс. мощность мотора 18.6 кВт

- Крутящий момент Нм

- Размер стола 850×400 мм

- Макс. мощность мотора 13 кВт

- Крутящий момент 82.7 Нм

- Размер стола 650×400 мм

- Макс. мощность мотора 7.5 кВт

- Крутящий момент 47.7 Нм

- Размер стола 1000×550 мм

- Макс. мощность мотора 22 кВт

- Крутящий момент 60 Нм

- Размер стола 800×800 мм

- Макс. мощность мотора 22 кВт

- Крутящий момент Нм

- Размер стола 540×1200 мм

- Макс. мощность мотора 30 кВт

- Крутящий момент Нм

- Размер стола 1000×1000 мм

- Макс. мощность мотора 35 кВт

- Крутящий момент 960 Нм

- Размер стола 1500×570 мм

- Макс. мощность мотора 18.5 кВт

- Крутящий момент 286 Нм

- Размер стола 800×800 мм

- Макс. мощность мотора 45 кВт

- Крутящий момент Нм

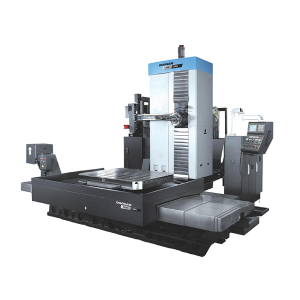

Горизонтально-расточные станки

Станки Doosan Machine Tools DBC имеют долговечную жесткую конструкцию для длительного поддержания точности и оснащены высокоскоростными мощными шпинделями для оптимальной производительности резания.

- Размер стола 8000×2200 мм

- Макс вес заготовки 20000 кг

- Мощность мотора 37 кВт

- Размер стола 8000×1500 мм

- Макс вес заготовки 7000 кг

- Мощность мотора 26 кВт

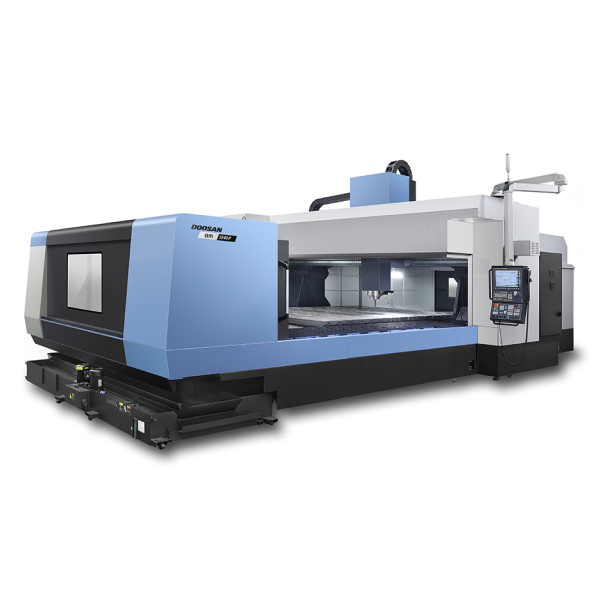

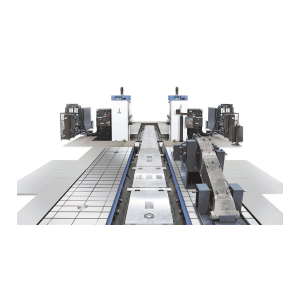

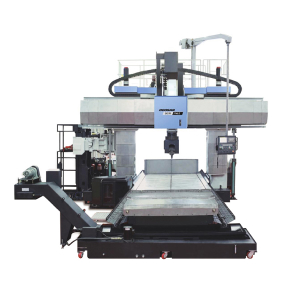

Портальные обрабатывающие центры

Серия обрабатывающих центров BM предназначена для высокоточной обработки больших тяжелых деталей.

Для обеспечения точности станок оснащен системой компенсации тепловой деформации с датчиками, расположенными вокруг шпинделя и конструкции, а также роликовыми направляющими и линейными шкалами, что обеспечивает высокую точность обработки.

- Расстояние между колоннами 4200 мм

- Макс. вес заготовки 45000 кг

- Макс. мощность мотора 45 кВт

- Расстояние между колоннами 3000 мм

- Размер стола 2500×8000 мм

- Макс. мощность мотора 45 кВт

- Расстояние между колоннами 2700 мм

- Макс. мощность мотора 30 кВт

- Крутящий момент 600 Нм